D71X Wafer Centerline Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

product drawing

D71X Wafer Centerline Butterfly Valve Series

Overview

The D71X Wafer-Type Centerline Butterfly Valve is a valve that controls the opening, closing, and regulation of fluid flow by rotating a disc-shaped butterfly plate around its fixed shaft (valve stem). The axis of the valve stem is located at the "centerline" position, where the sealing surface of the butterfly plate intersects with the centerline of the pipeline channel, ensuring symmetrical design on both sides of the butterfly plate. The valve features a wafer-type connection, meaning the valve body itself is flangeless and is clamped between two pipeline flanges using double-ended bolts. The sealing ring of the butterfly plate is typically made of elastic materials such as rubber and is directly embedded in the valve body or the inner ring of a pressure plate, achieving sealing by compressing the ring during butterfly plate rotation. The valve is operated manually, electrically, or pneumatically, driving the valve stem to rotate 90 degrees or less for rapid control of fluid flow, including on/off functions and flow regulation.

Features

1、Compact and Lightweight Design: The wafer-type construction ensures a short face-to-face dimension, small volume, and reduced weight, making it particularly suitable for piping systems with limited installation space.

2、Quick and Easy Operation: A 90° rotation of the disc completes the full opening or closing cycle, offering simple and rapid actuation with low operating torque.

3、Low Fluid Resistance: When fully open, the disc creates minimal obstruction to the flow, resembling a straight pipe section, resulting in low pressure loss.

4、Excellent Sealing Performance: The centerline sealing structure utilizes a resilient soft seat that fits tightly against the disc edge, providing effective bidirectional sealing (or unidirectional sealing, depending on the specific design), especially suitable for normal/low temperature and low-to-medium pressure applications.

5、Easy Maintenance and Cost-Effectiveness: With a simple structure and fewer components, disassembly and replacement are relatively straightforward. Compared to other valves of the same diameter, it generally offers advantages in both manufacturing and installation costs.

6、Wide Range of Applications: The valve body can be made from materials such as cast iron, ductile iron, or stainless steel, while the lining and disc may be selected from various corrosion-resistant materials or coatings. This versatility enables its use in pipelines handling liquids or gases across numerous industries, including water treatment, HVAC, water supply and drainage, gas, power, and chemical processing.

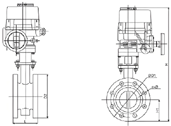

Dimensions & constructral diagram

D941X Electric Flange Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Name | Materials |

|---|---|

| Handle / Handwheel | Carbon Steel (or Cast Iron) |

| Stem | Stainless Steel (304/316) |

| Disc | Ductile Iron (Rubber-Lined) |

| Seal | Rubber (Nitrile NBR / EPDM) Rubber (Nitrile NBR / EPDM) |

| Seat | Rubber (Matching Seal Material) |

| Bolt / Nut | Carbon Steel (or Stainless Steel) |

| Body | Ductile Iron (or Stainless Steel) |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | MPa |

| Strength Test Pressure | 2.4 | MPa |

| Sealing Test Pressure | 1.76 | MPa |

| Applicable Temperature | ≤80 | ℃ |

The main external and connection dimensions

| DN | L | H | H0 | A | B | 0.6MPa | 1.0MPa | 1.6MPa | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Do | n-d | Do | n-d | Do | n-d | ||||||

| 50 | 43 | 63 | 235 | 270 | 110 | 110 | 4-14 | 125 | 4-18 | 125 | 4-18 |

| 65 | 46 | 70 | 250 | 270 | 110 | 130 | 4-14 | 145 | 4-18 | 145 | 4-18 |

| 80 | 46 | 83 | 275 | 270 | 110 | 150 | 4-18 | 160 | 8-18 | 160 | 8-18 |

| 100 | 52 | 105 | 316 | 270 | 110 | 170 | 4-18 | 180 | 8-18 | 180 | 8-18 |

| 125 | 56 | 115 | 340 | 310 | 110 | 200 | 8-18 | 210 | 8-18 | 210 | 8-18 |

| 150 | 56 | 137 | 376 | 310 | 110 | 225 | 8-18 | 240 | 8-22 | 240 | 8-22 |

| 200 | 60 | 164 | 430 | 353 | 150 | 280 | 8-18 | 295 | 8-22 | 295 | 12-22 |

| 250 | 68 | 206 | 499 | 353 | 150 | 335 | 12-18 | 350 | 12-22 | 355 | 12-26 |

| 300 | 78 | 230 | 570 | 380 | 150 | 395 | 12-22 | 400 | 12-22 | 410 | 12-26 |